CAGE CODE 3EGW3 | DUNS-053355991 My Account

X-ray Screening in Massachusetts

Smiths Detection has the most comprehensive range of X-ray and EDS screening solutions in the industry.

Whether you require a system for screening mail and parcels, personal bags at checkpoint security, baggage or freight, Smiths Detection has the technology and product to meet your needs.

ACS Your Massachusetts Smiths Detection X-ray & Smiths X-ray Partner

If you are in MA and are in need of Smiths X-ray checkpoint security products or service, give ACS a call

When it comes to Smiths Detection X-ray and Smiths X-ray distributors in Boston, Springfield, Worcester, New Bedford, Leominster, Cambridge, Lowell, Brockton, Quincy, Lynn MA, and more importantly the integration, maintenance and servicing of Smiths X-ray equipment throughout Massachusetts, count on ACS, for over 20 years experts in security and threat detection equipment and services!

In MA, Many organizations start looking for Smiths Detection X-ray Distributors as their first step in the specification, bid solicitation and procurement of Smiths Detection threat detection and screening technologies. Distributors in most industries historically provide equipment to the “trades”, companies such as consultants and traditional brick and mortar resellers. The term has somewhat become generalized to mean a supplier of Smiths Detection Equipment. But is this what you really need?

The answer is no. When it comes to the specification and deployment of critical security systems, you need specialists with tenure in the design and deployment of these technologies with their associated layered products and services. Why you may ask? Because your systems are critical to the safety of everyone involved and getting it wrong can be catastrophic. When you partner with an organization like Access Control Systems, a company with decades of experience in the industry deploying security and threat detection systems, you are getting experience in not only the procurement of Smiths Detection equipment, but decades of real-world experience in the deployment, running, maintenance and servicing of complete systems and solutions.

Why Smiths Detection X-ray and Access Control Systems as Your Technology Partners for MA Installations

Smiths Detection and their X-ray products have become somewhat synonymous with the term threat detection, sure there are other brands, but Smiths is one of the most well known in it’s class globally, and produces some of the finest technology and equipment in the threat detection and security screening industry. Many, if not most of the world’s most secure facilities, including those throughout MA, utilize Smiths Detection X-ray equipment and technologies in one way or another.

Partnering with ACS and it’s decades of experience in threat detection and screening solutions creates the perfect match, you get some of the industry’s best technologies with a provider that can design, right size, deploy, and maintain your system all in one vendor. ACS is considered in throughout the industry as one of the premier Value-Added Resellers and Services providers when it comes to Smiths Detection.

We welcome the opportunity to help you navigate the specification, procurement, deployment, management, and servicing of your Smith Detection security solution.

About Access Control Systems Your MA Smiths X-ray Partner

Access Control Systems, Inc., has been in the security industry for over 20 years and have a demonstrated track record of keeping your systems running and operational at all times.

Our services range from repairs of existing checkpoint security equipment, installations of new equipment, safe relocation, certifications, calibrations, to working with contracting companies on developing entirely new checkpoints. We strive to create both professional and personal relationships with our customers and manufacturers. We have over 20 years of experience in servicing most major brands of systems and parts for both current and discontinued systems. Our goal is to both create the most efficient checkpoints utilizing either existing or new equipment while maintaining the least amount of downtime or disturbance to your operation. As has been true for more than 20 years, ACS strives to provide both new and existing customers a industry best response times.

About Smiths Detection

Every minute of every day, Smiths Detection’s threat detection and security screening technology helps to protect people and infrastructure, making the world a safer place.

We deliver the solutions needed to protect society from the threat and illegal passage of explosives, prohibitive weapons, contraband, biological threats, toxic chemicals and narcotics.

Our goal is simple – to provide the security, peace of mind and freedom of movement upon which the world depends.

Learn More

Call ACS today and let one of our Smiths Detection equipment specialists help you understand your options as they apply to your specific needs and requirements. Trained as solution providers, our pre-sales engineers can ensure you don’t make a costly mistake by specifying the wrong equipment for your need. Just looking for a distributor, reseller or vendor to supply all of your Smiths Detection equipment, no problem, call us today and we can provide you a hassle-free consult and quote for Smiths Detection threat detection or security screening equipment as well as any post sale services you may require.

About ACS Control Systems

ACS Control Systems has been providing security screening and scanning equipment to organizations of all types for over 20 years. When it comes to threat detection and your organization you can rest assured knowing that our agnostic approach to your security challenges will provide you the most comprehensive and effective solution yielding the highest results possible while ensuring maximum human and product traffic throughputs. With ACS experience, and the industry’s leading security screening equipment manufacturers equipment such as Smiths Detection, Ceia, Garrett, and more, you will have better outcomes. Let us help you today down the path to a more secure existence!

Checkpoint.Evoplus

Advanced screening and management platform

Checkpoint.Evoplus helps individual components and sensors that are typically unable to communicate with each other and transforms them into a single, integrated and intelligent solution to advance the efficiency of your checkpoint.

Overview

Checkpoint.Evoplus is a digital-led solution that helps checkpoints achieve the highest level of security and improved operations by delivering critical insights and enabling remote screening.

Checkpoint.Evoplus’ intelligence software analyses data from various systems, sensors and components from across an entire screening area to generate a full range of invaluable insights. This data makes it easy to monitor performance metrics in real-time for faster and better decision-making.

Consolidated KPIs provide an overall view of the system status with clear audio and visual notifications drawing attention to any changes in the customised performance thresholds. It also generates historical data and reports required for resource planning and general administration. KPIs can be monitored and shared via a central dashboard which can also be accessed from mobile devices.

Networked images can be collected from all security lanes and delivered to a team of operators based at a remote location, away from the distractions of the busy checkpoint. Suspicious areas are marked and classified on the images, so staff at the checkpoint know exactly where to focus secondary inspections.

Checkpoint.Evoplus is compatible with both 2D and 3D screening, allowing for the benefits of the software to continue when upgrading to a 3D system, such as the HI-SCAN 6040 CTiX.

Overview

ECAC Standard 3 approved and TSA certified, the CTX 5800 explosive detection system (EDS) quickly identifies threats in checked baggage.

Using a single X-ray generator, the unit’s design provides high-resolution 3D images for quick and accurate threat detection in space or weight restricted environments.

It is compact but flexible, and with simple extensions can process anything from large duffle bags to skis and golf bags, making it ideal for smaller airports. For large airports you might be interested in our high speed EDS CTX 9800.

It can be fully integrated into a baggage handling system and offers networking solutions to link multiple scanners for efficient image distribution and system monitoring among operators.

CTX 5800

CT explosives detection system

A compact explosives detection system (EDS), the CTX 5800 identifies threats in checked baggage and cargo packages.

CTX 9800 DSi

High speed CT explosives detection system

ECAC Standard 3 approved and TSA certified explosives detection system (EDS) suitable for identifying threats in checked baggage and cargo packages.

Overview

The CTX 9800 DSi explosive detection system (EDS) uses a proprietary single X-ray source, dual energy design that provides high-resolution 3D images along with 2D and 3D organic/inorganic material discrimination.

These imaging tools enhance the analysis of details and specific structures of suspected threats, allowing for efficient security decisions on all checked bags and cargo packages.

Built on a scalable platform with upgrade capabilities to meet future detection and capacity requirements, the CTX 9800 DSi can be integrated with any baggage-handling system.

The system accepts large and elongated bags of up to 2.5m in length, reducing the need for separate processing of oversized luggage. Using a single conveyor belt, the CTX 9800 reduces bag slippage, and a single X-ray source reduces down-time caused by X-ray-tube failures.

It is also available with networking solutions that link multiple CTX EDS for efficient image distribution and system monitoring and control among operators.

For smaller airports you might be interested in our explosive detection system CTX 5800.

Overview

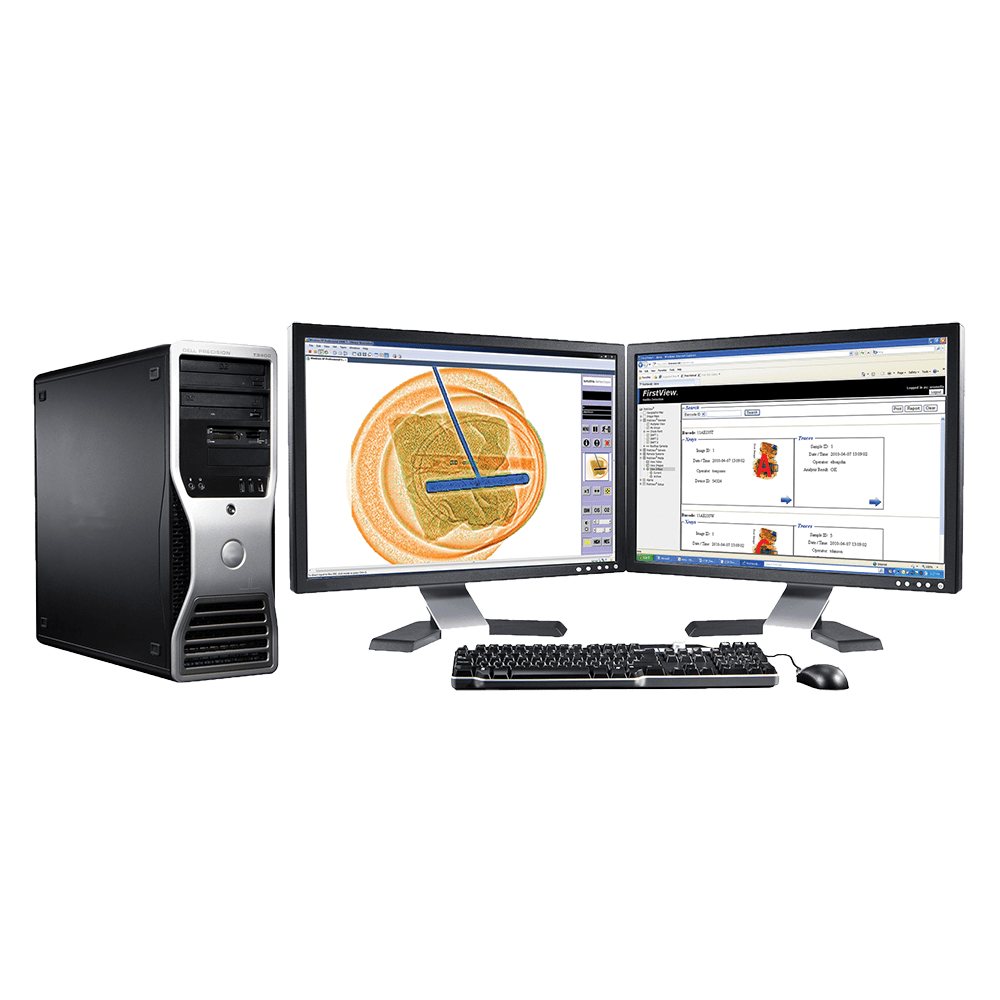

FirstView-LINX works over a standard Ethernet network to integrate HI-SCAN X-ray imaging and IONSCAN 500DT trace detection systems.

The simple and intuitive graphical user interface requires minimal operator training.

Based on a package’s shipping barcode, FirstView-LINX can automatically archive key data from our screening equipment – such as the X-ray image and/or trace results – including the date and time and the operator that screened the package.

FirstView-LINX

Archives, tracks, and retrieves screening results

A networking solution that enhances Smiths HI-SCAN X-ray and IONSCAN 500DT trace detection screening capabilities.

HI-SCAN 100100T

Single-view scanning for large objects

Ideal for inspecting over-sized baggage and freight, the HI-SCAN 100100T is a state-of-the-art X-ray inspection system for heavy objects up to a size of 100 x 100cm.

Overview

The HI-SCAN 100100T is a state-of-the art X-ray inspection system for scanning objects up to a size of 100 x 100cm.

Designed to meet the needs of airports, customs facilities, transportation operations, carriers and parcel services – in applications where high security and the screening of large objects are required.

The low installation height of the conveyor system facilitates the connection of supplementary feed and/or discharge conveyor systems for heavy freight.

Overview

Equipped with two generators arranged at a 90° angle to each other, the HI-SCAN 100100T-2is provides Dual-view screening of objects up to 100 x 100cm (39 x 39in). The dual-view screening mode provides reliable inspection of tightly packed objects in a single process, while shortening inspection times and increasing the effectiveness of the procedure.

With the low installation height of the HI-SCAN 100100T-2is conveyor belt, it is simple to connect supplementary feed and/or discharge conveyor systems for heavy freight.

Following IATA’s recommendations regarding Dangerous Goods, the HI-SCAN 100100T-2is is also available with an option for detecting lithium batteries.

HI-SCAN 100100T-2is

Dual-view scanner for large objects

Featuring a low conveyor belt, the dual-view X-ray HI-SCAN 100100T-2is is designed for screening over sized baggage and bulky freight.

HI-SCAN 100100V

Break-bulk cargo scanner

A compact X-ray security screening system, the HI-SCAN 100100V is designed for facilities requiring high-security screening of items up to a size of 100 x 100cm.

Overview

The HI-SCAN 100100V is a compact X-ray security screening system with tunnel dimensions of 100cm by 100cm.

Designed for facilities requiring high security screening of items with a large range of dimensions.

It permits the inspection of bulky as well as small items without any loss of X-ray image quality, and is designed to meet the needs and applications of airports, customs facilities, transportation operations, carriers and parcel services.

Overview

The HI-SCAN 100100V-2is is equipped with two 160kV generators in 90° opposition, providing a horizontal and vertical view of the screened object (dual-view). This screening method facilitates reliable inspections of tightly packed objects in one process, shortening inspection times.

Designed to meet the requirements of airports, customs facilities, logistics companies and parcel services, its compact system design provides the highest performance with the smallest footprint and offers two different conveyor speeds, 0.2 m/s and 0.5 m/s.

The high-speed HI-SCAN 100100V-2is model delivers high throughput break bulk cargo screening for fast turnaround, high volume air cargo applications.

The HI-SCAN 100100V-2is is available with an option for automatically detecting lithium batteries as well as weapons.

HI-SCAN 100100V-2is

Break-bulk cargo screening

Featuring a high-speed conveyor belt, the HI-SCAN 100100V-2is provides high-quality images of screened objects of different sized baggage and parcels.

HI-SCAN 10080 EDX-2is

Automatic explosives detection system

Using a dual view X-ray system, the HI-SCAN 10080 EDX-2is improved the evaluation process allows operators to ‘look behind’ objects while automatically screening baggage for explosives.

Overview

Within the proven multi-level method of checked-baggage screening, all baggage is screened automatically for explosives by a high-speed Level-1 system, the EDX-2is. Bags cleared by EDX-2is continue to their determined destination while rejected bags are automatically diverted to a second security level for further inspection, significantly.

With a tunnel opening of 1070mm x 810mm, the EDX-2is allows the screening of oversized objects up to 3.8m, avoiding the need for alternative screening.

With its high detection capability, combined with a low false-alarm rate, the system can screen up to 1,800 bags per hour.

Automatic detection of lithium batteries (iCMORE Lithium Batteries) is offered as an option on this scanner.

Overview

The HI-SCAN 10080 XCT is a next generation high-speed, explosives detection system (EDS) for hold baggage and air cargo. It features a dual-view dual-energy X-ray line scanner with full 3D volumetric computed tomography (CT) imaging and reconstruction.

The HI-SCAN 10080 XCT has a belt speed of 0.5m/sec (98.5ft/min) and a large 107 x 81 cm (42.1 x 31.9in) rectangular tunnel. It is designed to be integrated into fully automated and networked baggage and material handling systems. This combination offers airports a throughput of up to 1,800 bags/hour and air cargo handlers the capability to screen 2,500 parcels/hour.

The HI-SCAN 10080 XCT has qualified under the U.S. Safety Act, which sets limited liability for claims related to terrorism. It is TSA certified for high-speed checked baggage screening and EU/ ECAC EDS Standard 3.0 and 3.1 approved.

Automatic detection of dangerous goods such as lithium batteries (iCMORE Lithium Batteries) as well as flammable solids and liquids, compressed and liquefied gases (iCMORE Dangerous Goods) is offered as an option on this scanner.

HI-SCAN 10080 XCT

Advanced CT explosives detection system

Complying with current TSA and ECAC regulations, the HI-SCAN 10080 XCT explosives detection system generates high-speed, checked baggage.

HI-SCAN 130130T-2is

Heavy freight X-ray system

The HI-SCAN 130130T-2is has been designed to handle heavy freight and europallets ideal for screening air cargo.

Overview

The HI-SCAN 130130T-2is has been designed for the inspection of heavy freight and Euro pallets.

Its low installation height is ideal for conveyor belts, and the connection of supplementary feed and discharge conveyor systems for heavy freight is simple.

It is equipped with two generators beaming in two directions (dual view). The second beam direction is displaced at 90°, facilitating reliable inspections of even tightly packed objects in a single process, shortening inspection times and increasing effectiveness.

Typical penetration is 35mm of steel in view 2 and 30mm in view 1, while the maximum conveyor load is 250kg (550lbs).

Overview

Suitable for the inspection of air cargo transported on standard Euro, British or US pallets, the HI-SCAN 145180 is designed to meet the needs of warehouses, carriers, forwarders and couriers for airports.

The HI-SCAN 145180 is a low-energy (160kV) X-ray inspection system with tunnel dimensions of 1,450mm (57in) width and 1,800 mm (71in) height.

Also available the dual view HI-SCAN 145180 2is

HI-SCAN 145180

Scanner for palletised lower-deck cargo

This cargo inspection screening unit is designed to meet the needs of warehouses, carriers, forwarders and couriers for airports.

HI-SCAN 145180-2is

Large objects dual view scanner

Universal X-ray system for palletised items, ideal for use in warehouses. Dual view for shorter inspection times.

Overview

The HI-SCAN 145180-2is has two 160kV generators in a 90° opposition providing a horizontal and vertical view of the object (dual-view) for shortened inspection time and high-quality images.

The tunnel dimensions of 1,450mm (57in) width and 1,800mm (71in) height is suitable for the inspection of air cargo transported on standard Euro, British or US pallets.

For large-scale cargo screening, check the Advanced HI-SCAN 180180 2is pro.

Overview

The innovative air cargo screening system HI-SCAN 145180-2is pro meets the demand for fast turnaround, high levels of security and an attractive total cost of ownership (TCO).

This state-of-the-art scanner is equipped with two 200 kV X-ray generators, one of which is uniquely positioned under the conveyor belt, to deliver excellent penetration, superior image quality, more efficiency, and easy access for maintenance and service.

In-depth research and extensive testing were undertaken to establish the optimum generator design for a long lifespan. This is just one contributing factor in the impressively low TCO – others include cost of spare parts; easy service access; and, as space is such an expensive commodity, the particularly compact footprint.

The generators are digitally controlled enabling advanced analysis and diagnosis capabilities and there is also an internal memory, storing important lifecycle data. Equipped with the latest HiTraX 3 CS electronics, the HI-SCAN 145180-2is pro offers state-of-the-art technology for advanced software features and image processing.

A robust conveyor features tightly packed rollers to support smooth passage through the inspection tunnel for pallets and other bulky and heavy objects. The large tunnel handles objects up to 145cm x180cm. Integration into material handling systems is straightforward.

HI-SCAN 145180-2is pro

Fast, effective air cargo screening

The innovative air cargo screening system HI-SCAN 145180-2is pro meets the demand for fast turnaround, high levels of security and an attractive total cost of ownership (TCO).

HI-SCAN 180180-2is pro

Advanced dual view X-ray cargo scanner

An X-ray scanner designed for the inspection of large scale consolidated and palletised goods, ideal for cargo inspection.

Overview

An X-ray scanner designed for the inspection of large-scale consolidated and palletised goods.

Tunnel dimensions of 180 x 180cm means the HI-SCAN 180180-2is pro is capable of screening LD3 containers.

Based on a dual-view concept, the system provides two sharp independent views of the screened goods and, as a result, it delivers more accurate and reliable image evaluation.

Two powerful 300 kV X-ray generators are capable of penetrating even large and dense objects, reducing reinspection times (as consolidated cargo does not usually need to be broken down into smaller items), ensuring high throughput and a fast, efficient inspection process.

The small-pitch roller conveyors ensure a smooth passage for the scanned goods and supports a total load of up to 5,000kg/m (evenly distributed).

Overview

The HI-SCAN 5030C X-ray scanner is an ideal solution for screening mail and personal belongings in commercial and public buildings due to its size, mobility and durability.

The HI-SCAN 5030C is specifically designed to enhance security screening operations from courthouses to corporate campuses. Its compact size and lightweight construction enable it to fit seamlessly into checkpoints and mailrooms. Vibration absorbers make it possible to transport HI-SCAN 5030C between various locations without requiring re-calibration, providing maximum flexibility.

Featuring proven HiTrax 3 electronics and software platform to enhance and expedite security screening operations. It produces reliable and easy-to-interpret scanned images enabling screening personnel to make threat and contraband assessment of parcels to personal items quickly and confidently.

The HI-SCAN 5030C is available as a stationary desktop scanner or as a mobile version on wheels featuring vibration shock absorbers and a storage compartment.

HI-SCAN 5030C

Compact & mobile X-ray inspection system

A transportable and lightweight X-ray scanner, ideal for screening in mail rooms or building entrances, including: courthouses, schools, event venues, stadiums or correctional facilities.

HI-SCAN 6040 CTiX

Advanced screening using CT technology

Meeting the highest available regulatory standards, the HI SCAN 6040 CTiX is now available with ECAC EDS CB C3 approval and TSA AT-2 certification.

Overview

The HI-SCAN 6040 CTiX offers advanced screening of carry-on baggage using Computed Tomography (CT). It has TSA APSS 6.2 Level 1 certification as well as ECAC and STAC EDS CB C3 approval. C3 approved systems deliver a very high level of explosives detection and can also scan baggage without removing electronic devices and liquids – expediting screening and makes the whole process less stressful for passengers.

The 6040 CTiX gantry rotates at a constant speed as baggage is carried through it on the conveyor belt. Hundreds of images are taken to create 3D images in real-time, allowing for more accurate judgments on the bag contents.

HI-SCAN 6040 CTiX can be integrated with iCMORE automatic weapon detection.

Overview

An advanced dual-view X-ray inspection system for the automatic detection of solid and liquid explosives in personal belongings and cabin baggage. The HI-SCAN 6040-2is HR has an ergonomic design that makes it easy for the operator to identify threats on screen.

Approved for ECAC EDS CB C1 means that it can be used for the screening of checked cabin baggage. It also meets EU legislation for LEDS Standard 2 and 3 Type C – an extended approval as a Liquid Explosive Detection System (LEDS).

Using proven X-ray technology, it generates reliable, high-quality dual-view images, and it is also available in standard resolution (not approved for aviation cabin baggage).

Though primarily used for airport screening, its compact footprint makes it suitable for locations with space constraints such as hotels and government buildings.

HI-SCAN 6040-2is HR

Dual view X-ray inspection for carry-on luggage

An advanced dual-view X-ray inspection system for the automatic detection of solid and liquid explosives in checked baggage.

HI-SCAN 6040aTiX

X-ray inspection system

An advanced multi-view X-ray system for the automatic detection of solid and liquid explosives in cabin baggage.

Overview

HI-SCAN 6040aTiX is an advanced multi-view X-ray system for the automatic detection of solid and liquid explosives in cabin baggage.

The detection performance of HI-SCAN 6040aTiX is far superior to other automatic systems, including lower false-alarm rates. Using advanced computer technologies, complex analyses can be carried out in real-time, maximising baggage throughput without hampering normal checkpoint procedures.

The two detailed views support the quick and reliable evaluation process.

It was the industry’s first system to achieve ECAC LEDS Type C Standard 2 certification for screening of liquids, and has since gained LEDS Type C Standard 3 as well as EDS CB C1 and C2 for cabin baggage.

Overview

HI-SCAN 6040C is designed to screen bags, parcels and other objects for prohibited and dangerous items at building entrances.

Generating highly detailed, easily interpreted X-ray images, with a background-contrast function that improves the recognizability of objects on the screen.

Intelligent image-display functions support the operator in the rapid and reliable distinction of organic and inorganic threats.

It can also provide real-time diagnostics on its operating status, ensuring easy handling and troubleshooting.

HI-SCAN 6040C

Airport quality screening for buildings & events

Designed to screen bags and parcels for prohibited and dangerous items, the HI-SCAN 6040C is ideal for screening at building entrances.

HI-SCAN 6040i

Ideal for screening at checkpoints and building entrances

This X-ray unit is ideal for screening personal belongings and cabin baggage at aviation checkpoints and building entrances.

Overview

This X-ray unit is for screening personal belongings and cabin baggage at airport checkpoints and critical infrastructure.

It is easy to operate and increases throughput at security checkpoints. Its material discrimination technology ensures reliable image analysis.

The HI-SCAN 6040i is the most successful X-ray inspection system in its class, with more than 12,000 installations worldwide.

Overview

Due to it’s size and tunnel opening the HI-SCAN 7555aTiX is very versatile and suitable for application in the fields of cabin baggage, hold baggage or parcel screening.

The HI-SCAN 7555aTiX provides automatic detection of solid and liquid explosives during the screening of checked or hold baggage, parcels or small items of air cargo.

An aperture opening of 75 x 55cm, combined with a maximum duty conveyor load of 250kg, provides the flexibility to screen a wide range of items, including heavier freight items.

Performing with high detection and very low false alarm rates, the HI-SCAN 7555aTiX can be fully integrated into network environments for system management, facilitating archiving, image distribution and TIP functionalities.

In addition to achieving ECAC EDS Standard 2 for hold-baggage screening, the HI-SCAN 7555aTiX has achieved certification for ECAC EDS cabin baggage C1 and C2. It also meets the EU legislation for LEDS Standard 2 and 3 Type C.

HI-SCAN 7555aTiX

Versatile automatic explosives detection system

With automatic detection of solid and liquid explosives, the HI-SCAN 7555aTiX is ideal for the screening of hand luggage, hold baggage, parcels and small air cargo.

HI-SCAN 7555aX

Dual view EDS checkpoint screening system

A state-of-the-art dual view X-ray inspection system, using independent multi-energy generators to screen baggage and small cargo thoroughly .

Overview

A state-of-the-art dual view X-ray inspection system, using independent multi-energy generators to screen baggage and small cargo thoroughly .

HI-SCAN 7555aX allows for explosive and contraband detection at security checkpoints.

Its modular system platform facilitates in-field upgrades to full four view automated explosives and liquid detection system, while retaining it’s original footprint.

Overview

The HI-SCAN 7555i provides high-quality image analysis for the screening of checked baggage and packages.

A compact X-ray inspection system with a tunnel opening of 755 (w) x 555 (h) [mm]. This tunnel size suits the unit to screening checked luggage and packages as well as briefcases, handbags and other small items.

The HI-SCAN 7555i offers operators optimum support in making decisions and reduces inspection times considerably with its online image analysis methods, and a new ergonomic man-machine interface.

HI-SCAN 7555i

Compact X-ray inspection system

The HI-SCAN 7555i provides high quality image analysis for the screening of checked baggage and packages.

HI-SCAN 7555si

Advanced X-ray inspection

With large tunnel dimensions and an advanced multi energy X-ray generator, the HI-SCAN 7555si provides high quality image analysis of baggage and parcels.

Overview

Using an advanced multi-energy X-ray generator, the HI-SCAN 7555si produces extremely detailed X-ray images with more than double the number of pixels compared to other systems. The enhanced image resolution of the scanned objects represents a decisive advantage for image evaluation.

The HI-SCAN 7555si features a large tunnel opening and can therefore scan objects that exceed the aviation industry’s standard dimensions for hand baggage.

Can be integrated in networks for system management, archiving, image distribution and TIP functionalities.

Overview

The HI-SCAN 9075 scans items up to 90 x 76cm (width x height), making it ideal for screening bulky objects, including oversized baggage and freight.

Heavy objects can be easily placed on the conveyor belt, which is only 35cm above the ground. The low installation height facilitates the connection of supplementary feed and/or discharge conveyor systems for heavy freight.

The HI-SCAN 9075 is also available as a mobile unit.

HI-SCAN 9075

X-ray scanner for freight

Provides high-quality X-ray scanning of bulky objects, over-sized objects, making it ideal for screening of baggage and freight.

incent.control

Web-based system-management platform

Brings mobility, flexibility, cost reduction and IT security to those, responsible for managing security checkpoints, explosive detections systems or any other Smiths Detection sensor product.

Overview

A web-based management platform for CXS/EDS networks, incent.control provides mobility, flexibility, cost reduction and IT security to those responsible for managing security checkpoints, explosives detection systems or any other networked Smiths Detection sensor product.

Can be used for checkpoints, hold-baggage screening systems, X-ray units, trace products and other sensors.

Using incent.control, the user’s web browser is connected with the Smiths Detection server. The application being delivered by the server, there is no need to install any software onto individual devices.

In existing MatriX Server or HMS systems, the activation of incent.control requires only a software update of the server.

incent.control is complementary to existing HMC workstations.

Overview

Incent.view 2D/3D capable workstation allows for high-quality on-screen image resolution combined with ergonomic and intuitive operation.

Incent.view’s image-evaluation features include infinite zoom, single-alarm processing, colour intensity and grey-level absorption, and the full set of HI-TraX-based X-ray units.

Marking and annotation of suspicious areas, workflow integration as Analyst (remote screening) and Recheck, and configuration as either a 2D or 3D workstation are available.

incent.view

3D & 2D analyst and recheck workstation

incent.view workstations allow the review and analysis of X-ray images from all Smiths Detection HiTraX based X-ray systems.

MatriX Server

System management and image distribution system

Connecting X-ray units and operator workstations, the MatriX Server helps to manage the distribution of images and results within a multi-level X-ray network.

Overview

The MatriX Server enables networking functions and software applications. It is the essential core of any networking solution in many different market sectors, including ports and borders, urban security, defence and, of course, aviation.

In aviation, the major applications supported by the server are system management and X-ray image distribution for hold baggage and checkpoint screening – driven by advanced screening and management platforms such as Checkpoint.Evoplus.

It facilitates everything from small networks and functions such as centralised screening and real-time management data, to linking large, international airport groups. Up to 600 X-ray scanners can be supported by one MatriX Server.

Each system is assembled and configured according to individual customer requirements and tested to ensure turn-key operation. Premium components and commercially available standard hardware, deliver excellent reliability.

Additional features include extended temperature range; spatial redundancy solutions; single mode optical fibre technology; and external data interfaces to support risk-based screening and remote maintenance.

Overview

MUX allows multiple operators to view bags from single or multiple explosives detection systems, resulting in more efficient screening and better use of personnel.

With built-in redundancy to ensure network dependability, leading industry-standard switches and servers, and hot-swappable components to minimize downtime, our networking solutions help to increase security and to lower operational costs – while optimizing the use of critical personnel. Designed to be flexible and highly customizable, our infrastructure future-proofs your investment as your airport’s needs grow and change.

It is highly customizable to fit the exact needs of any airport, and flexible enough to accommodate new regulations or passenger growth.

MUX

Networking systems

MUX links the CTX systems with user and control interfaces for remote screening of checked baggage.